|

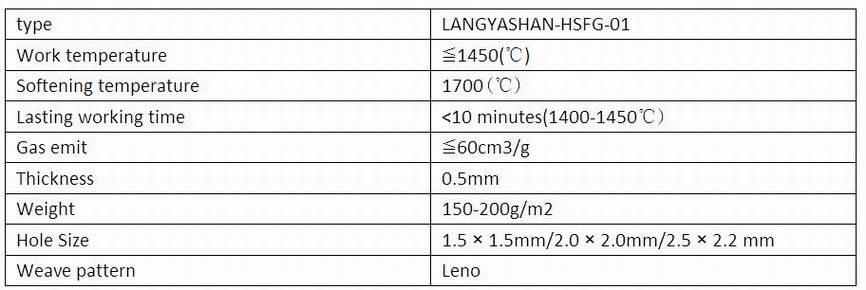

Iron Casting Filter: high silica glass fiber casging filter (common)

-for filtering gray, ductile and small steel castings

Iron casting filter uses high silica glass fiber grid and abrasive mesh as material and it's covered by heat resistant coatings. Comparing with others, this kind of casting filter is cheaper and more convenient to use, not changing any metal parts of the casting and it has a better filtration effect and low gas evolution.Besides, it is also high-temperature and corrosion resistant, with high steel strength and chemical stability to prevent metal melt erosion. The molten iron casting filter is an ideal filter material for all metal melts and can also be used for filtering chemical corrosive liquid and hot gas.

Mesh sizes include  ,etc and can also be customized. ,etc and can also be customized.

Products Features

1. Simplify the gating system and more castings can be put on the template, greatly improving the casting yield.

2. Eliminate the adverse effects caused by harmful elements on the organization structure and material properties of the casting, raising the ductile iron casting plasticity by more than 10%.

3. Heighten casting's mechanical performance and reduce the damage to the cutting tool and prolong its service life.

4.Prevent the metallic solution from turbulence and vortex to stabilize filling and decrease the second oxidation, greatly enhancing the inner and outer quality of the casting.

5.Effectively remove the impurity and reduce the defects like casting inclusion and air holes over a half, significantly lowering the inferior products rate.

Caution in Use

1.Put the casting filter near the runner on the cavity as close as possible to better prevent the floating sand.

2.To simplify the operation and have a good effect, it is suggested to put the net on the parting surface, where the runners joint and it would also be better to put the runners of the inlet direction in the top tank because it can limit the impurities floating and reduce the pressure on the molten iron.

3.When the runners can not joint because of some reasons, filter net can be installed on the cross section of the runners or gates. Under this circumstance, the runners must be put in the top tank owing to the inclusion can not move on the molten metal and the gap in the lower part of the net can not block the slags. However, if the cross section is too big or wide, the filter net will be distorted by the high temperature, extending the gap and weakening the blocking effect.

4.The space of the filter net should be fixed in the pouring system to avoid the movement brought by the lash of molten metal and further affect the blocking function. Generally, the blank pressed by sand should be 15mm for each in wet type casting system. If the blank embedded in the runners can be narrow, it can be extended to 20-30mm for the dry one.

|